When it comes to electrical installations, selecting the correct wire size is crucial for safety and efficiency. For a 100 amp service, the wire size must be carefully chosen to handle the current load without overheating or causing hazards. Understanding the factors that influence the choice of wire size can save you from costly mistakes and ensure your electrical system operates smoothly. Many homeowners and electricians often wonder what gauge wire is appropriate for a 100 amp service. The answer depends on several factors, including the length of the wire run, the material of the wire, and local building codes.

Choosing the wrong wire size can lead to voltage drop issues, inefficient energy use, and even fire hazards. Copper and aluminum are the two most common materials used for wiring, and each has its own requirements for a 100 amp service. Copper wires are more conductive and can carry the same current with a smaller gauge compared to aluminum wires. However, aluminum wires are often more cost-effective, making them a popular choice for larger installations.

Additionally, the length of the wire run plays a significant role in determining the appropriate wire size. Longer runs require thicker wires to minimize voltage drop and ensure consistent power delivery. Local building codes and regulations also dictate the minimum wire size for a 100 amp service, so it’s essential to consult these guidelines before making a decision. By understanding these factors, you can ensure that your electrical system is safe, efficient, and compliant with all necessary standards.

Read also:Exploring The Lives Of Odell Beckham Jr And Justin Bieber A Fascinating Journey

Table of Contents

- What Is the Right Wire Size for 100 Amp Service?

- How Does Wire Material Affect 100 Amp Size Wire Choice?

- Why Is Voltage Drop Important for 100 Amp Wiring?

- What Are the Local Codes for 100 Amp Size Wire?

- How to Calculate Wire Size for 100 Amp Service?

- Common Mistakes to Avoid with 100 Amp Wiring

- Benefits of Using Copper vs. Aluminum for 100 Amp Size Wire

- Factors Influencing Wire Size Selection for 100 Amp Service

- Tools and Resources for Selecting 100 Amp Size Wire

- Final Thoughts on 100 Amp Size Wire Choices

What Is the Right Wire Size for 100 Amp Service?

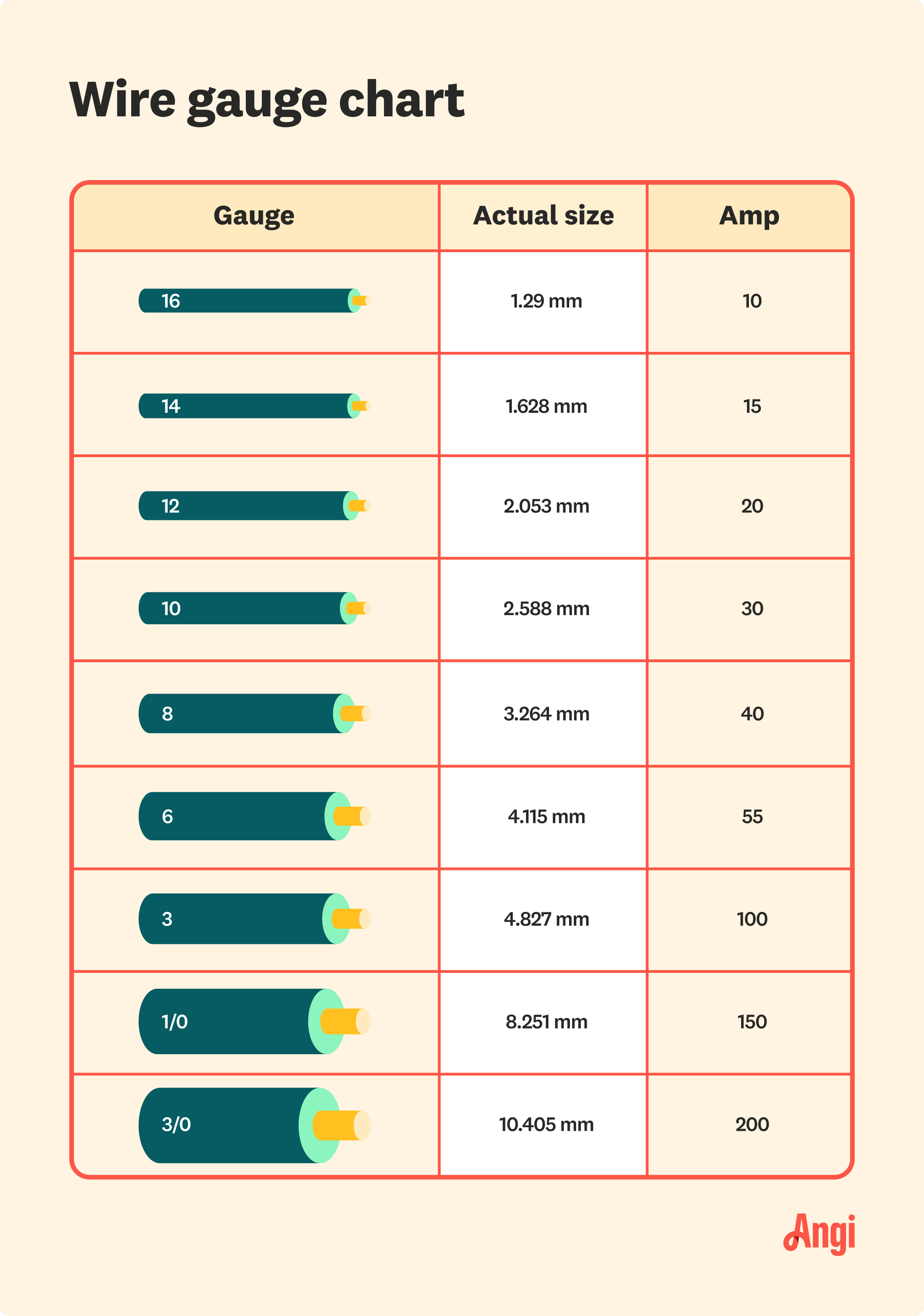

For a 100 amp service, the National Electrical Code (NEC) provides guidelines to ensure safety and efficiency. Typically, a copper wire with a gauge of 3 AWG or an aluminum wire with a gauge of 1 AWG is recommended. These sizes are designed to handle the current load while minimizing the risk of overheating. However, the exact wire size may vary depending on the specific application and local regulations.

When selecting a wire, it’s important to consider the insulation type as well. Wires with higher temperature ratings, such as THHN or XHHW, can handle more current and are often preferred for 100 amp services. Additionally, the wire’s insulation should be compatible with the environment where it will be installed, whether it’s indoors, outdoors, or in a conduit.

How Does Wire Material Affect 100 Amp Size Wire Choice?

The material of the wire plays a significant role in determining the appropriate size for a 100 amp service. Copper wires are more conductive, allowing them to carry the same current with a smaller gauge compared to aluminum wires. For example, a 3 AWG copper wire can handle the same load as a 1 AWG aluminum wire.

Aluminum wires, on the other hand, are lighter and less expensive, making them a popular choice for larger installations. However, they require larger gauges to compensate for their lower conductivity. It’s essential to weigh the pros and cons of each material based on your specific needs and budget.

Why Is Voltage Drop Important for 100 Amp Wiring?

Voltage drop occurs when the electrical current encounters resistance in the wire, leading to a loss of voltage along the length of the wire. For a 100 amp service, excessive voltage drop can result in inefficient energy use and potential damage to appliances. To minimize voltage drop, it’s crucial to choose the right wire size for the length of the run.

The NEC recommends keeping voltage drop below 3% for branch circuits and 5% for feeder circuits. This can be achieved by using thicker wires for longer runs. For example, if your 100 amp service requires a 100-foot wire run, you may need to upgrade to a larger gauge wire to maintain acceptable voltage levels.

Read also:Christina Schwarzenegger A Deep Dive Into Her Life Career And Legacy

What Are the Local Codes for 100 Amp Size Wire?

Local building codes and regulations play a vital role in determining the appropriate wire size for a 100 amp service. These codes are designed to ensure safety and compliance with industry standards. Before starting any electrical project, it’s essential to consult the local building authority or a licensed electrician to understand the specific requirements in your area.

In some regions, the minimum wire size for a 100 amp service may be larger than the NEC recommendations to account for environmental factors or other considerations. For example, areas with extreme temperatures or high humidity may require thicker wires to ensure safe operation.

How to Calculate Wire Size for 100 Amp Service?

Calculating the appropriate wire size for a 100 amp service involves several steps. First, determine the length of the wire run and the material of the wire. Then, use a voltage drop calculator or consult a wire size chart to find the recommended gauge for your specific application.

Here’s a simple formula to calculate voltage drop:

- Voltage Drop = (2 x Length x Current x Resistance) / 1000

By plugging in the values for your project, you can determine whether the chosen wire size will meet the voltage drop requirements. If the voltage drop exceeds the recommended limit, consider upgrading to a larger gauge wire.

Common Mistakes to Avoid with 100 Amp Wiring

When working with 100 amp wiring, it’s easy to make mistakes that can compromise safety and efficiency. One common error is underestimating the wire size needed for the project. Using a wire that’s too small can lead to overheating, voltage drop issues, and even fire hazards.

Another mistake is ignoring local building codes and regulations. Failing to comply with these guidelines can result in fines, project delays, or unsafe installations. Always consult a licensed electrician or building inspector before proceeding with any electrical work.

Benefits of Using Copper vs. Aluminum for 100 Amp Size Wire

Copper and aluminum each have their own advantages and disadvantages when used for 100 amp wiring. Copper wires are more conductive, allowing them to carry the same current with a smaller gauge. This makes them ideal for installations where space is limited or where higher efficiency is desired.

On the other hand, aluminum wires are lighter and more cost-effective, making them a popular choice for larger projects. However, they require larger gauges to compensate for their lower conductivity. Ultimately, the choice between copper and aluminum depends on your specific needs, budget, and application.

Factors Influencing Wire Size Selection for 100 Amp Service

Several factors influence the selection of wire size for a 100 amp service. These include the length of the wire run, the material of the wire, the insulation type, and local building codes. Each of these factors plays a crucial role in ensuring the safety and efficiency of your electrical system.

For example, longer wire runs require thicker wires to minimize voltage drop and ensure consistent power delivery. Similarly, the choice between copper and aluminum wires depends on factors such as cost, space, and conductivity requirements. By considering all these factors, you can make an informed decision that meets your specific needs.

Tools and Resources for Selecting 100 Amp Size Wire

There are several tools and resources available to help you select the right wire size for a 100 amp service. Online calculators, wire size charts, and industry guides can provide valuable insights into the appropriate gauge for your project. Additionally, consulting with a licensed electrician or building inspector can ensure compliance with local codes and regulations.

Some popular tools include voltage drop calculators, which help you determine the acceptable wire size based on the length of the run and the material of the wire. These tools can save you time and effort by providing accurate recommendations tailored to your specific application.

Final Thoughts on 100 Amp Size Wire Choices

Selecting the right wire size for a 100 amp service is a critical decision that impacts the safety, efficiency, and compliance of your electrical system. By understanding the factors that influence wire size selection, such as material, length, and local codes, you can make an informed choice that meets your needs.

Whether you choose copper or aluminum, it’s essential to prioritize safety and efficiency. Always consult a licensed electrician or building inspector to ensure your installation complies with all necessary standards. With the right wire size and proper installation, you can enjoy a reliable and efficient electrical system for years to come.