When it comes to electrical systems, safety and efficiency are paramount, especially when dealing with a 100 amp service. Choosing the correct wire gauge is critical to ensure your system operates safely and meets local electrical codes. The wire needed for 100 amp service must be carefully selected based on factors like distance, material type, and environmental conditions. Using the wrong wire can lead to overheating, power loss, or even fire hazards, making it essential to understand the requirements before installation.

Many homeowners and electricians face confusion when determining the appropriate wire gauge for a 100 amp service. Copper and aluminum are the two most common materials used, each with its own advantages and considerations. Copper wires are more conductive but tend to be more expensive, while aluminum is cost-effective but requires larger gauges to handle the same load. Knowing which material suits your needs ensures a reliable and long-lasting electrical setup.

Additionally, the length of the wire run plays a significant role in determining the wire gauge. Longer distances require thicker wires to minimize voltage drop, which can affect the performance of your appliances and devices. Understanding these factors is essential to avoid costly mistakes and ensure your electrical system is both safe and efficient. Let’s dive deeper into the specifics of selecting the right wire for your 100 amp service.

Read also:How To Access Iot Devices Anywhere Using Ssh With Aws As An Example

Table of Contents

- What Is the Wire Needed for 100 Amp Service?

- Why Is Selecting the Right Wire Important?

- What Are the Common Materials Used for Wire?

- How Does Wire Length Affect Your Choice?

- What Are the Local Codes and Regulations?

- How to Calculate Voltage Drop?

- What Are the Best Practices for Installation?

- Can You Use Aluminum Wire for 100 Amp Service?

- How to Maintain Your Electrical System?

- Frequently Asked Questions

What Is the Wire Needed for 100 Amp Service?

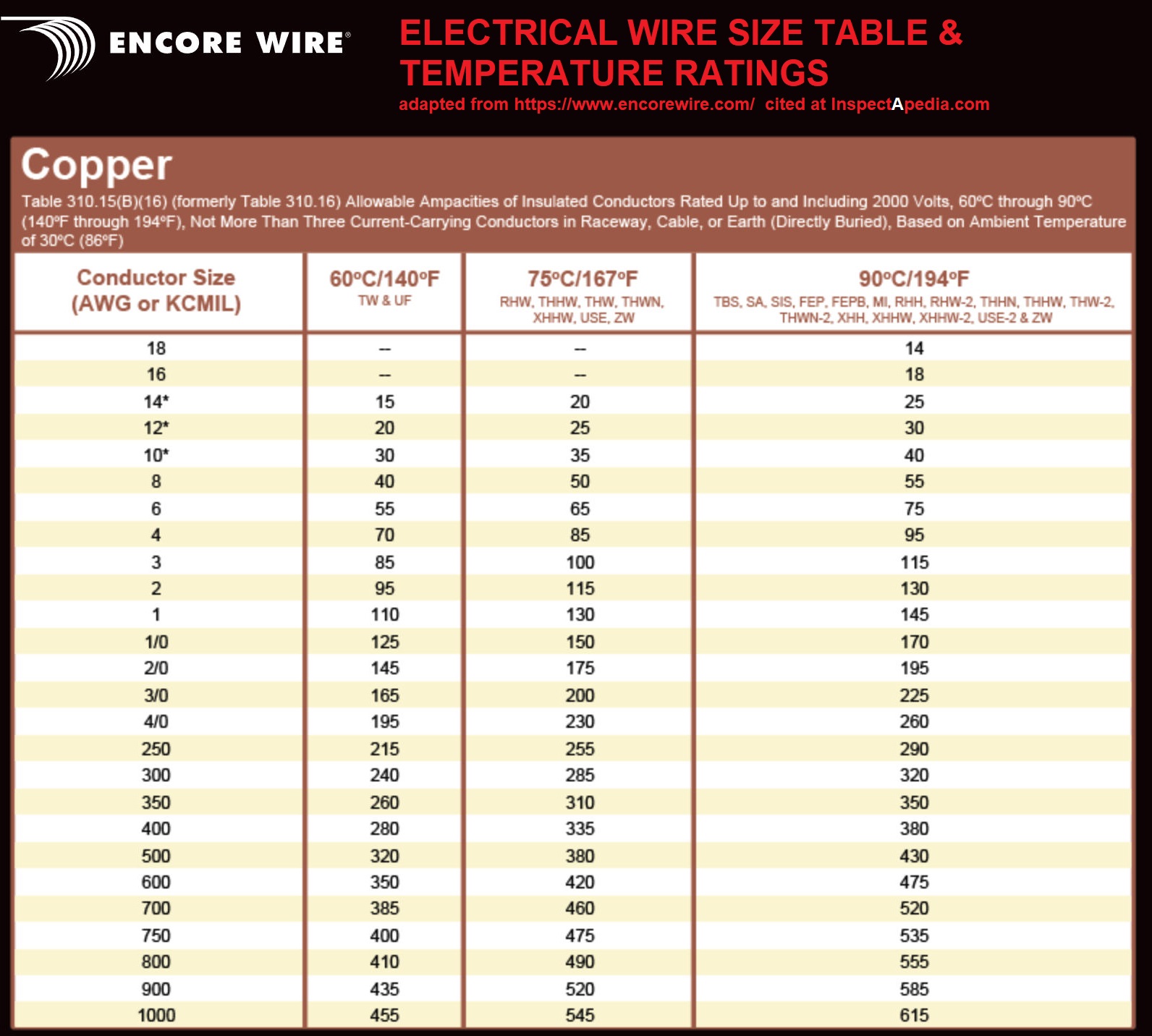

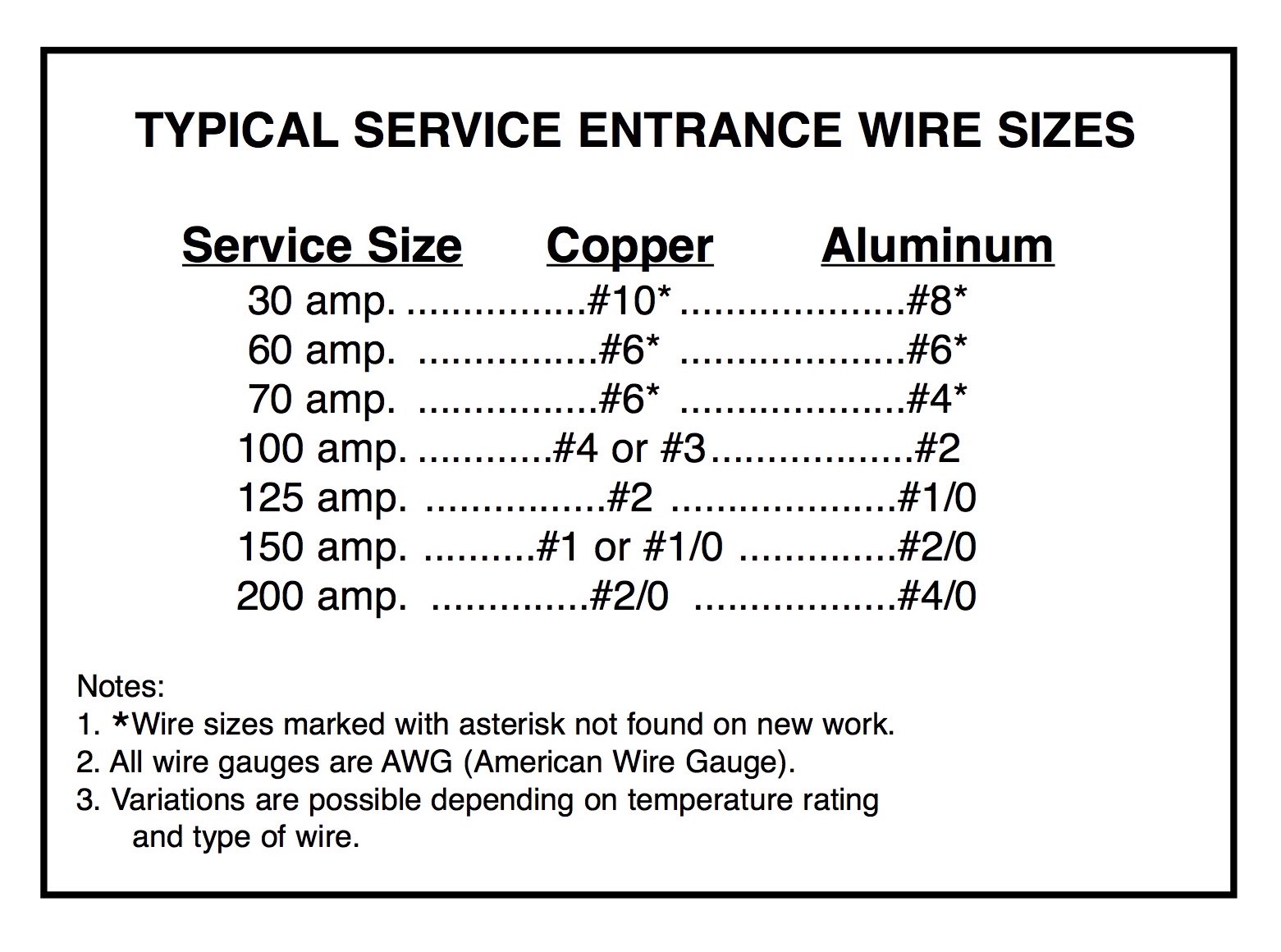

The wire needed for 100 amp service typically ranges between 2 AWG and 4 AWG for copper wires, depending on the distance and environmental conditions. For aluminum wires, the recommended gauge is usually 1/0 AWG to ensure safe and efficient operation. These wire sizes are designed to handle the high current demands of a 100 amp service without overheating or causing voltage drops that could damage your appliances.

Choosing the correct wire gauge is not just about meeting the ampacity requirements but also about ensuring compliance with the National Electrical Code (NEC). The NEC provides guidelines on wire sizing based on the type of insulation, ambient temperature, and other factors. Adhering to these standards is crucial to avoid penalties and ensure the safety of your electrical system.

Why Is Copper Preferred for 100 Amp Service?

Copper is often the preferred material for the wire needed for 100 amp service due to its superior conductivity and durability. It can carry more current than aluminum at the same gauge, making it ideal for shorter runs or installations where space is limited. However, copper wires are more expensive, which is why some homeowners opt for aluminum as a cost-effective alternative.

Why Is Selecting the Right Wire Important?

Selecting the right wire for your 100 amp service is crucial for several reasons. First and foremost, it ensures the safety of your home and family by preventing overheating and potential fire hazards. Using an undersized wire can lead to excessive heat buildup, which may damage the insulation and cause electrical failures.

Secondly, the correct wire size ensures optimal performance of your appliances and devices. Voltage drop, which occurs when the wire is too thin or too long, can reduce the efficiency of your electrical system and lead to inconsistent power supply. This is particularly important for high-demand appliances like air conditioners, water heaters, and electric stoves.

What Are the Risks of Using Incorrect Wire?

Using the wrong wire for your 100 amp service can have serious consequences. Undersized wires can overheat, melt insulation, and potentially start a fire. On the other hand, oversized wires can be unnecessarily expensive and difficult to work with. Both scenarios highlight the importance of consulting a professional electrician or using reliable resources to determine the wire needed for 100 amp service.

Read also:Jaden Smith P Diddy Unveiling Their Influence Legacy And Impact

What Are the Common Materials Used for Wire?

The two most common materials used for electrical wiring are copper and aluminum. Each material has its own advantages and disadvantages, making it essential to weigh your options carefully before making a decision.

What Are the Benefits of Copper Wire?

Copper is highly conductive, corrosion-resistant, and durable, making it an excellent choice for the wire needed for 100 amp service. It requires smaller gauges to carry the same current as aluminum, which makes it ideal for tight spaces. However, the higher cost of copper can be a deterrent for some homeowners.

Why Choose Aluminum Wire?

Aluminum is a cost-effective alternative to copper and is often used in larger installations where budget constraints are a concern. While it is less conductive than copper, aluminum wires are lighter and easier to handle. However, they require special connectors and anti-oxidant compounds to prevent corrosion and ensure a secure connection.

How Does Wire Length Affect Your Choice?

The length of the wire run is a critical factor when determining the wire needed for 100 amp service. Longer distances result in higher resistance, which can lead to voltage drop and reduced efficiency. To compensate for this, thicker wires are required to maintain optimal performance.

For example, a 100-foot run may require a 2 AWG copper wire, while a 200-foot run might need a 1/0 AWG aluminum wire. Calculating the voltage drop and selecting the appropriate wire gauge ensures that your electrical system operates safely and efficiently, regardless of the distance.

How to Minimize Voltage Drop?

To minimize voltage drop, consider using thicker wires or reducing the distance between the power source and the load. Additionally, upgrading to copper wires can help reduce resistance and improve performance. Always consult an electrician to ensure your system meets the required standards and operates efficiently.

What Are the Local Codes and Regulations?

Local electrical codes and regulations play a significant role in determining the wire needed for 100 amp service. These codes are designed to ensure safety and compliance with industry standards. Failure to adhere to these regulations can result in fines, penalties, or even the inability to sell your home in the future.

Before starting any electrical project, it is essential to consult your local building department or a licensed electrician to understand the specific requirements for your area. This includes wire gauge, material type, and installation methods that comply with the National Electrical Code (NEC) and local amendments.

How to Calculate Voltage Drop?

Calculating voltage drop is an important step in selecting the right wire for your 100 amp service. The formula for voltage drop is:

Voltage Drop = (2 x Length x Current x Resistance) / 1000

Where:

- Length is the distance of the wire run in feet

- Current is the amperage of the circuit

- Resistance is the resistance per 1,000 feet of the wire

Using this formula, you can determine the appropriate wire gauge needed to minimize voltage drop and ensure efficient operation.

Why Is Voltage Drop Important?

Voltage drop is important because it affects the performance of your electrical system. Excessive voltage drop can lead to dimming lights, reduced appliance efficiency, and even equipment failure. By selecting the correct wire gauge for your 100 amp service, you can minimize voltage drop and ensure consistent power delivery.

What Are the Best Practices for Installation?

Proper installation is just as important as selecting the right wire for your 100 amp service. Follow these best practices to ensure a safe and efficient setup:

- Use the correct connectors and terminals for the wire material (copper or aluminum).

- Avoid overloading circuits by distributing the load evenly across multiple circuits.

- Securely fasten wires to prevent movement and reduce the risk of damage.

- Label all wires and circuits for easy identification during maintenance or upgrades.

Can You Use Aluminum Wire for 100 Amp Service?

Yes, you can use aluminum wire for 100 amp service, but it requires careful consideration and proper installation. Aluminum wires are larger in diameter than copper wires, so they may not fit in standard connectors without modifications. Additionally, aluminum is more prone to corrosion, so anti-oxidant compounds must be applied to ensure a secure connection.

What Are the Challenges of Using Aluminum Wire?

One of the main challenges of using aluminum wire for 100 amp service is its lower conductivity compared to copper. This means that aluminum wires need to be thicker to carry the same current, which can make installation more difficult. Additionally, aluminum is more prone to expansion and contraction, which can lead to loose connections over time.

How to Maintain Your Electrical System?

Regular maintenance is essential to ensure the longevity and safety of your electrical system. Here are some tips for maintaining your 100 amp service:

- Inspect wires and connections periodically for signs of wear or corrosion.

- Test circuit breakers and outlets to ensure they are functioning properly.

- Keep the area around your electrical panel clean and free of obstructions.

- Hire a licensed electrician for annual inspections and any necessary repairs.

Frequently Asked Questions

What is the wire needed for 100 amp service?

The wire needed for 100 amp service typically ranges between 2 AWG and 4 AWG for copper and 1/0 AWG for aluminum, depending on the distance and environmental conditions.

Can I use aluminum wire for 100 amp service?

Yes, aluminum wire can be used for 100 amp service, but it requires proper installation techniques and anti-oxidant compounds to prevent corrosion.

How does wire length affect voltage drop?

Longer wire runs increase resistance, leading to higher voltage drop. Thicker wires are required to compensate for this and ensure efficient operation.

What are the local codes for 100 amp service?

Local codes vary by region, so it’s essential to consult your local building department or a licensed electrician to ensure compliance with the National Electrical Code (NEC) and any local amendments.