Choosing the correct wire size for a 100 amp panel is crucial for ensuring the safety and efficiency of your electrical system. Whether you're installing a new electrical panel or upgrading an existing one, understanding the appropriate wire gauge can prevent overheating, electrical fires, and system failures. Electrical codes and standards dictate the minimum requirements, but other factors like the distance from the power source and the type of wire used also play a significant role. This guide will walk you through everything you need to know to make the right choice for your project.

Electrical systems are the backbone of any home or business, and the wire size is one of the most critical components. If the wire is too small for the current load, it can lead to voltage drops, inefficiencies, and even dangerous situations. On the other hand, using a wire that's unnecessarily large can lead to wasted materials and higher costs. To make the best decision, it’s essential to understand the relationship between amperage, wire gauge, and the specific needs of your setup. This article will provide clear, actionable advice to help you determine the right size wire for a 100 amp panel.

With the increasing demand for reliable and safe electrical systems, homeowners and electricians alike are seeking accurate information about wire sizing. The complexity of electrical codes and the variety of materials available can make this task seem daunting. However, by breaking down the key factors and addressing common questions, this guide aims to simplify the process. Let’s dive into the details to ensure your electrical installation meets all safety standards and functions optimally.

Read also:Table of ContentsMastering Aws Remoteiot Vpc Ssh Download Free A Comprehensive Guide

- What Size Wire for a 100 Amp Panel?

- Why Does Wire Size Matter?

- How Far Can You Run a 100 Amp Wire?

- What Are the Common Wire Types for a 100 Amp Panel?

- How to Calculate the Right Wire Size?

- What Are the Electrical Codes for 100 Amp Wiring?

- What Are the Signs of Wrong Wire Sizing?

- Why Should You Hire a Professional Electrician?

- How to Avoid Common Mistakes in Wiring?

- Frequently Asked Questions

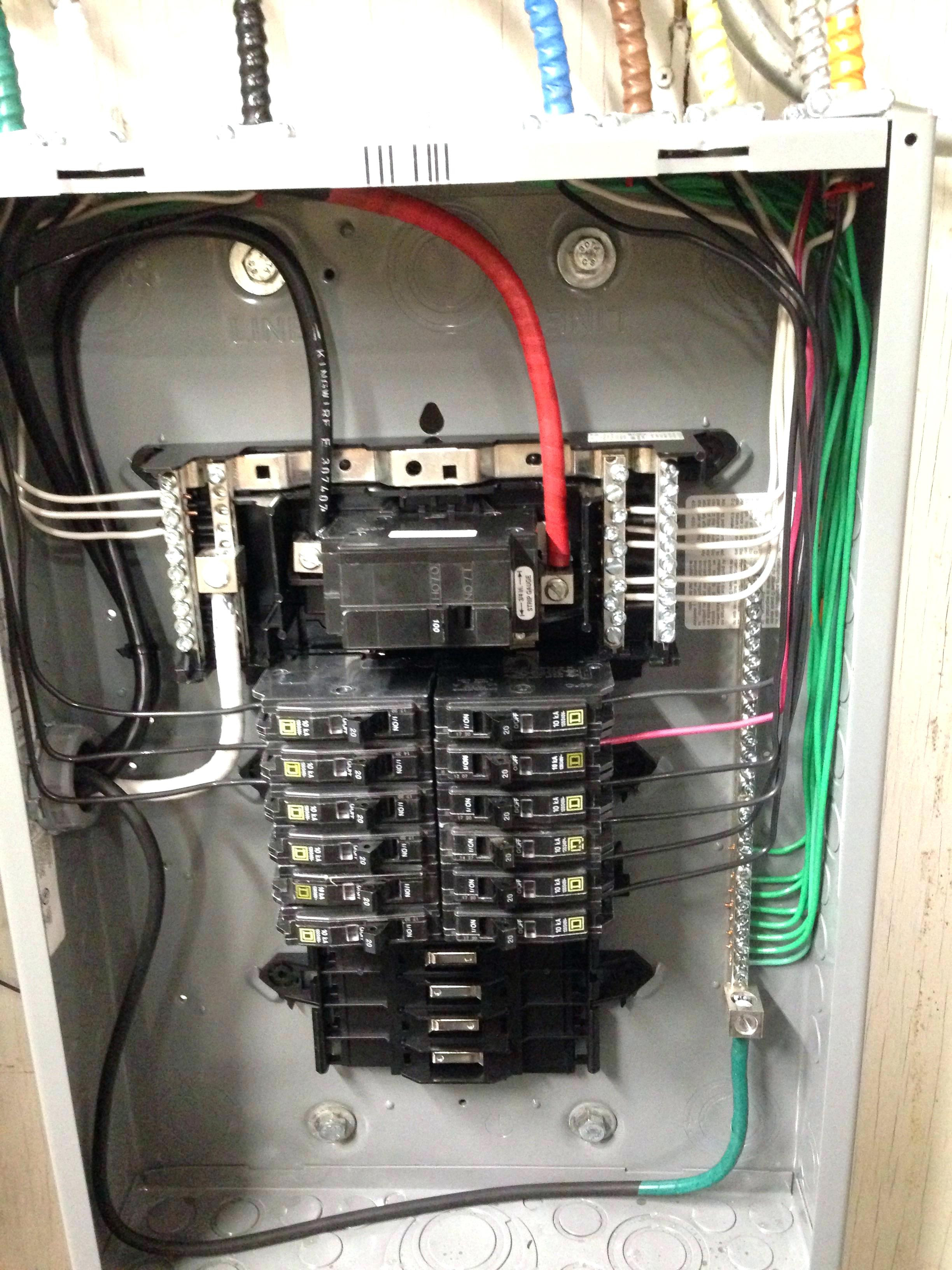

What Size Wire for a 100 Amp Panel?

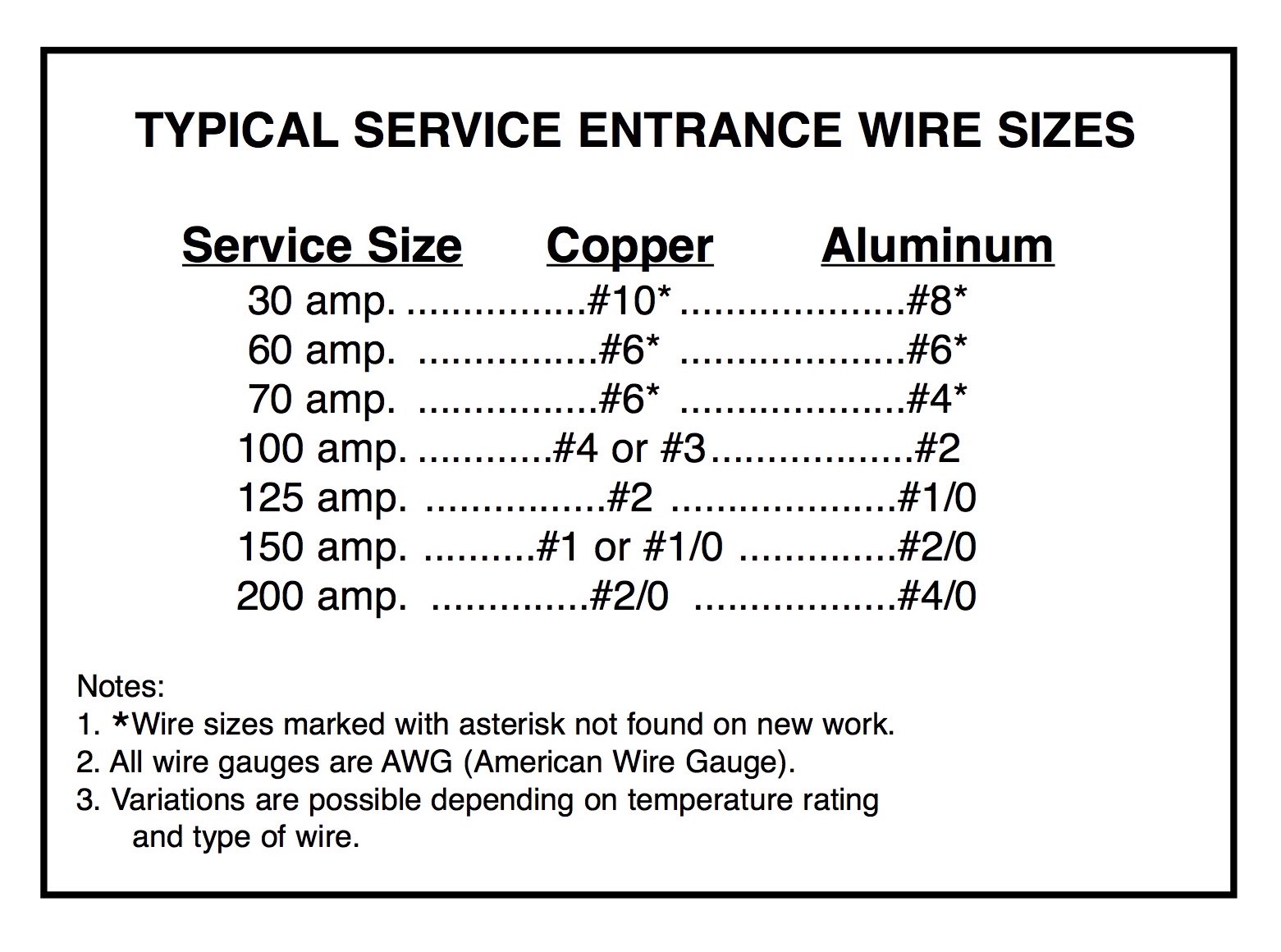

The most common wire size for a 100 amp panel is **3 AWG copper** or **1 AWG aluminum**. These sizes are based on the National Electrical Code (NEC) guidelines, which specify the minimum wire gauge required to safely carry 100 amps of current. Copper wires are preferred for their superior conductivity, but aluminum wires are often used for cost savings, especially in larger installations. However, aluminum wires require careful handling to avoid issues like corrosion or loose connections.

When determining the wire size for a 100 amp panel, it’s important to consider the distance between the power source and the panel. For shorter runs (less than 50 feet), 3 AWG copper or 1 AWG aluminum is typically sufficient. For longer distances, you may need to increase the wire size to compensate for voltage drop. Always consult the NEC or a licensed electrician to ensure compliance with local regulations.

Why Does Wire Size Matter?

Wire size directly impacts the safety and performance of your electrical system. If the wire is too small for the current it needs to carry, it can overheat, leading to melted insulation, damaged equipment, or even electrical fires. Conversely, using a wire that’s too large can be unnecessarily expensive and cumbersome to install. Properly sizing the wire ensures that your system operates efficiently and safely.

How Far Can You Run a 100 Amp Wire?

The distance you can safely run a 100 amp wire depends on the wire gauge and material. For copper wires, 3 AWG is suitable for runs up to 50 feet, but for distances exceeding 100 feet, you may need to upgrade to 2 AWG or larger. Aluminum wires generally require larger gauges to achieve the same performance as copper wires. Always account for voltage drop, which can reduce the efficiency of your electrical system over long distances.

What Are the Common Wire Types for a 100 Amp Panel?

There are two primary types of wires used for 100 amp panels: copper and aluminum. Each has its advantages and considerations:

- Copper: Offers better conductivity and is more durable but tends to be more expensive.

- Aluminum: More cost-effective and lighter but requires special connectors to prevent corrosion.

How to Calculate the Right Wire Size?

To calculate the correct wire size for a 100 amp panel, you need to consider the following factors:

Read also:Corbin Bleu A Multifaceted Talent Who Continues To Shine

- Amperage of the circuit (in this case, 100 amps).

- Distance from the power source to the panel.

- Type of wire material (copper or aluminum).

- Allowable voltage drop (typically 3% for branch circuits).

Using a voltage drop calculator or consulting the NEC charts can help you determine the appropriate wire gauge for your specific setup.

What Are the Electrical Codes for 100 Amp Wiring?

The NEC provides specific guidelines for wiring a 100 amp panel. These include:

- Minimum wire size requirements based on amperage.

- Grounding and bonding specifications.

- Conduit and insulation standards.

Always ensure your installation complies with the latest NEC edition and any local amendments.

What Are the Signs of Wrong Wire Sizing?

Incorrect wire sizing can lead to several issues, including:

- Frequent circuit breaker trips.

- Overheating wires or outlets.

- Flickering lights or inconsistent power supply.

If you notice any of these signs, it’s important to have your system inspected by a professional electrician immediately.

Why Should You Hire a Professional Electrician?

While DIY projects can be rewarding, electrical work is best left to licensed professionals. A qualified electrician can ensure that your wiring is up to code, properly sized, and installed safely. They can also identify potential issues that may not be obvious to an untrained eye.

How to Avoid Common Mistakes in Wiring?

To avoid common wiring mistakes, follow these tips:

- Always double-check wire size and material before installation.

- Use the correct connectors and terminals for aluminum wires.

- Plan for future upgrades or expansions to avoid costly rework.

Frequently Asked Questions

What size wire for a 100 amp panel is recommended for a 150-foot run?

For a 150-foot run, you may need to use 2 AWG copper or 1/0 AWG aluminum to account for voltage drop.

Can I use aluminum wire for a 100 amp panel?

Yes, but ensure you use proper connectors and follow all safety guidelines to prevent issues like corrosion.

What happens if the wire size is too small for a 100 amp panel?

Using a wire that’s too small can lead to overheating, electrical fires, and system failures.

How do I know if my wire size is correct?

Consult the NEC charts, use a voltage drop calculator, or hire a licensed electrician to verify your installation.

What size wire for a 100 amp panel is required by the NEC?

The NEC requires a minimum of 3 AWG copper or 1 AWG aluminum for a 100 amp panel.

By understanding the importance of wire size and following the guidelines outlined in this article, you can ensure a safe and efficient electrical installation. Whether you're a homeowner or a professional electrician, making informed decisions about wire sizing is essential for the longevity and reliability of your electrical system.