Electrical systems are the backbone of modern homes, and a 150 amp service is a common requirement for many households. The wire gauge you choose depends on several factors, including the distance of the run, the material of the wire, and local building codes. Copper and aluminum are the two most common materials used for wiring, each with different ampacity ratings. Copper wires are more conductive and require a smaller gauge compared to aluminum for the same current load. This guide will walk you through everything you need to know about what gauge wire for 150 amp service to ensure your electrical setup meets safety standards.

Choosing the correct wire gauge is not just about meeting the ampacity requirements but also about ensuring long-term durability and performance. Factors such as temperature, insulation type, and environmental conditions can affect the wire's ability to handle the load. By understanding these variables, you can make an informed decision that balances safety, cost, and efficiency. This article will answer all your questions about what gauge wire for 150 amp service and provide practical tips for a successful installation.

Table of Contents

- What Gauge Wire for 150 Amp Service?

- Why Wire Gauge Matters for Electrical Safety?

- How to Choose the Right Wire for 150 Amp Service?

- Common Mistakes to Avoid When Selecting Wire Gauge

- Copper vs. Aluminum Wires: Which is Better for 150 Amp Service?

- What Are the Building Codes for 150 Amp Service Wiring?

- How Does Distance Affect Wire Gauge Selection?

- Is Insulation Important for 150 Amp Service Wiring?

- How to Install Wires Safely for 150 Amp Service?

- Frequently Asked Questions About What Gauge Wire for 150 Amp Service

What Gauge Wire for 150 Amp Service?

The most common wire gauge for a 150 amp service is 2/0 AWG for copper wires and 4/0 AWG for aluminum wires. These sizes are based on the National Electrical Code (NEC) guidelines, which specify the minimum wire size to handle the current safely. However, these are general recommendations, and the actual gauge may vary depending on the specific conditions of your installation.

Read also:Mastering The El Patron Shot A Complete Guide To Dominating The Game

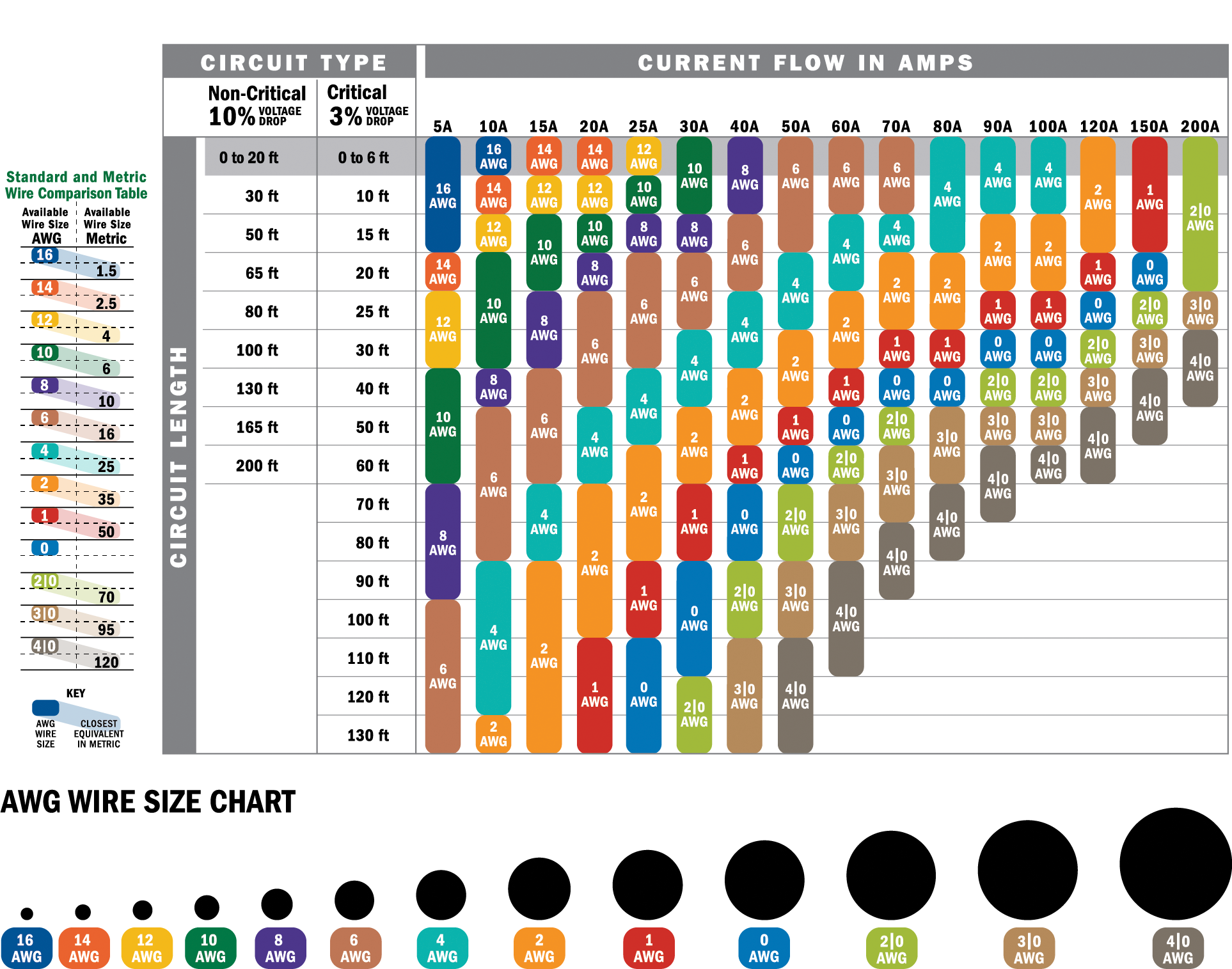

For example, if the distance between the electrical panel and the point of use is long, you may need to increase the wire gauge to compensate for voltage drop. Voltage drop occurs when the electrical resistance in the wire causes a reduction in voltage, leading to inefficient performance of appliances. To avoid this, it's essential to calculate the voltage drop and adjust the wire size accordingly.

Why Wire Gauge Matters for Electrical Safety?

Using the wrong wire gauge can have serious consequences, including overheating, fires, and equipment damage. A wire that is too small for the current load will generate excessive heat, which can melt the insulation and cause short circuits. On the other hand, using a wire that is too large can be unnecessarily expensive and difficult to work with.

The gauge of the wire determines its ampacity, or the maximum current it can safely carry. For a 150 amp service, the wire must have an ampacity rating that matches or exceeds the load. This ensures that the wire can handle the current without exceeding its temperature rating.

How to Choose the Right Wire for 150 Amp Service?

Choosing the right wire for 150 amp service involves several steps. First, determine the material of the wire—copper or aluminum. Copper is more conductive and requires a smaller gauge, while aluminum is lighter and less expensive but requires a larger gauge.

- Step 1: Check the NEC guidelines for minimum wire size.

- Step 2: Calculate the voltage drop based on the distance of the run.

- Step 3: Consider the temperature rating of the insulation.

Common Mistakes to Avoid When Selecting Wire Gauge

One of the most common mistakes is underestimating the importance of wire gauge. Some people assume that any wire labeled for 150 amps will work, but this is not always true. Factors such as distance, insulation, and environmental conditions can significantly impact the wire's performance.

Another mistake is ignoring local building codes. While the NEC provides general guidelines, local codes may have additional requirements. Always consult with a licensed electrician or local authority to ensure compliance.

Read also:Exploring The Iconic Career And Life Of Tommy Lee Jones A Hollywood Legend

Copper vs. Aluminum Wires: Which is Better for 150 Amp Service?

Copper and aluminum are the two most common materials used for electrical wiring. Copper is more conductive, durable, and resistant to corrosion, making it the preferred choice for many applications. However, it is also more expensive.

Aluminum, on the other hand, is lighter and less costly, but it requires a larger gauge to handle the same current. It is also more prone to corrosion and requires special connectors to prevent oxidation. When deciding between copper and aluminum, consider your budget, the specific requirements of your installation, and long-term maintenance costs.

What Are the Building Codes for 150 Amp Service Wiring?

Building codes play a crucial role in ensuring the safety and reliability of electrical installations. The NEC sets the standards for wire size, insulation, and installation practices, but local codes may impose additional requirements.

For example, some areas may require specific types of insulation for outdoor installations or mandate the use of conduit for added protection. Always check with your local building authority to ensure compliance with all applicable codes.

How Does Distance Affect Wire Gauge Selection?

The distance between the electrical panel and the point of use is a critical factor in determining the wire gauge. Longer runs result in higher resistance, which can cause voltage drop and reduce the efficiency of your electrical system.

To compensate for voltage drop, you may need to increase the wire gauge. The NEC recommends limiting voltage drop to 3% for branch circuits and 5% for feeders. Use a voltage drop calculator to determine the appropriate wire size for your specific installation.

Is Insulation Important for 150 Amp Service Wiring?

Insulation is a vital component of electrical wiring, as it protects the wire from environmental factors and prevents electrical shocks. The type of insulation you choose depends on the application and the conditions of the installation.

For example, THHN/THWN insulation is commonly used for indoor installations, while UF-B insulation is suitable for outdoor and underground applications. Make sure the insulation is rated for the voltage and temperature of your installation.

How to Install Wires Safely for 150 Amp Service?

Proper installation is just as important as selecting the right wire gauge. Follow these tips to ensure a safe and reliable installation:

- Turn off the power before starting any electrical work.

- Use the correct connectors and terminals for the wire material.

- Secure the wires properly to prevent movement and damage.

Frequently Asked Questions About What Gauge Wire for 150 Amp Service

What gauge wire for 150 amp service is recommended for short runs? For short runs, 2/0 AWG copper or 4/0 AWG aluminum is typically sufficient. However, always check for voltage drop and local codes.

Can I use a smaller gauge wire for 150 amp service if I reduce the load? While reducing the load may allow for a smaller gauge, it's best to use the recommended size to ensure safety and future-proofing.

What are the risks of using the wrong gauge wire for 150 amp service? Using the wrong gauge can lead to overheating, fires, and equipment damage, compromising the safety of your electrical system.